Nrog rau qhov ntsuas qhov tseeb, cov lus teb ceev ceev, muaj peev xwm tiv thaiv kev cuam tshuam, WLX-II yam ntsuas kub tsis tu ncua ntawm cov hlau molten muaj lub sijhawm hauv online saib xyuas molten steel kub variation, uas yog lub domestic tiam tshiab high-precision molten steel kub ntsuas. khoom.Los ntawm daim ntawv thov nyob rau hauv ntau yam steel nroj tsuag, kev ntseeg tau thiab stability ntawm cov khoom yog txaus affirmed.Nws yog tseeb cov khoom zoo tshaj plaws los hloov platinum rhodium thermocouple thermodetector.

Kev ntsuas kub: 700-1650 ℃

Tsis paub meej ntawm kev ntsuas: ≤ ± 3 ℃

Lub neej ntawm qhov kub thiab txias: ≥24 teev (Cov raj kub ntawm lub neej sib txawv tuaj yeem tsim tau raws li qhov xwm txheej ntawm qhov chaw)

Kev siv kub: 0-70 ℃ (detector), 5-70 ℃ (lub teeb liab processor)

Cov zis tawm tswv yim: 4-20mA / 1-5V (xws li 1450-1650 ℃)

Tso zis tsav zog: ≤400Ω (4-20mA)

Qhov tseeb tso zis: 0.5

Fais fab mov: AC220V ± 10V, 50HZ

Hwj chim: teeb liab processor 30W thiab loj screen zaub 25W.

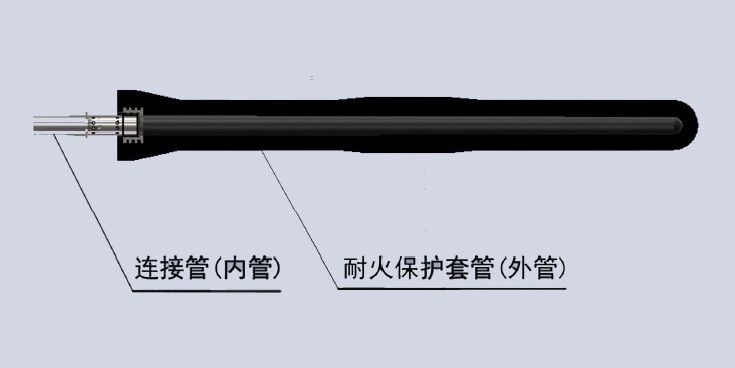

Lub raj kub kub muaj cov raj txuas txuas thiab hluav taws kub tiv thaiv casing.Qhov hluav taws kub tiv thaiv casing yog nyob rau hauv kev twb kev txuas nrog lub detector los ntawm kev sib txuas raj.Raws li qhov sib txawv qhov tob ntawm tundish molten steel thiab corrosion ntawm molten steel rau kub tube, qhov ntev ntawm qhov kub muaj specifications ntawm 1100mm, 1000mm thiab 850mm;txoj kab uas hla muaj specifications ¢ 85mm thiab ¢ 90mm, uas tuaj yeem kho raws li cov neeg siv khoom xav tau.

Kub tube yog ncaj qha tso rau hauv molten steel kom pom qhov kub thiab txias;qhov tob tob yuav tsum tsis pub tsawg tshaj 280mm.Kev ntsuas qhov ntsuas kub yog los ntawm sab hauv sab hauv qab ntawm lub raj sab nraud;lub sij hawm teb ntawm qhov ntsuas qhov pib sib npaug rau lub sij hawm lub zog xa tawm ntawm sab nraud ntawm hauv qab ntawm lub raj kub mus rau sab hauv.Kev sib txuas lub raj yog siv rau kev sib txuas ntawm lub raj kub thiab lub ntsuas ntsuas.Sab hauv lub raj yog tsuas yog tshem tawm cov pa luam yeeb hauv lub raj thiab xyuas kom huv ntawm txoj kev teeb.

| Yam khoom | Lub cev | Aluminium-magnesium-carbon slag kab | Magnesium slag kab |

| Al2O3% | 54.8-56.2 | 61.7-62.2 | 22.7-23.3 Nws |

| SiO 2% | 7.0-8.0 Nws | ||

| ZrO2% | |||

| MgO% | 8.5-9.0 Nws | 41.4-42.0 Nws | |

| FC% | 27.1-27.9 Nws | 25.0-25.4 Nws | 29.2-30.0 Nws |

| Volume ceev g/cmz | 2.46-2.53 Nws | 2.71-2.79 Nws | 2.48-2.52 Nws |

| Pom tseeb porosity% | 11.5-14.8 Nws | 11.4-13.8 Nws | 11.8-12.8 Nws |

| Txias crushing zog MPa | 20.9-32.9 Nws | 21.2-27.6 Nws | 20.7-26.7 Nws |

| Flexural zog ntawm qhov kub thiab txias MPa | 20.9-32.9 Nws | 5.4-7.3 | 5.5-8.3 |

Lub detector muaj xws li optical Cheebtsam, photoelectric converter, teeb liab kis tau tus mob kab, tso zis plug thiab cua txias duct, thiab lwm yam. input davhlau ya nyob twg ntawm lub detector txuas nrog txuas lub raj kub tube;cov zis davhlau ya nyob twg txuas nrog lub teeb liab processor ntawm 6P plug;input thiab output terminals yog kev cob cog rua los ntawm cov teeb liab kis tau tus mob kab tiv thaiv los ntawm lub saj zawg zog cua txias duct.Lub tshuab kho qhov muag xa cov teeb liab infrared hluav taws xob xa tawm hauv qab ntawm lub raj kub mus rau photoelectric converter, tom qab ntawd lub photoelectric converter hloov cov teeb liab kho qhov muag rau hauv hluav taws xob teeb liab thiab tom qab ntawd xa mus rau lub teeb liab processor ntawm cov teeb liab kis kab mob.

Cov teeb liab processor muaj lub zog module, analog teeb liab ua module, analog-digital conversion module, digital processing module, kev sib txuas lus module thiab zaub module, thiab lwm yam.

Lub teeb liab processor muaj kev ua haujlwm ntawm ob chav kub them nyiaj, uas tuaj yeem ua rau tsis siv neeg them nyiaj rau kev ntsuas qhov sib txawv los ntawm ib puag ncig qhov kub thiab txias ntawm qhov ntsuas ntsuas.

Lub teeb liab processor tau txais hluav taws xob teeb liab tawm tswv yim los ntawm tus ntes;ntsuas kub ntawm cov hlau molten yog xam los ntawm microprocessor raws li infrared tawg txoj kev xav thiab tso tawm rau ntawm qhov screen.Lub sijhawm no, cov ntaub ntawv ntsuas kub ntawm lub sijhawm tuaj yeem pom ntawm lub vijtsam loj los ntawm kev sib txuas lus muaj nuj nqi.Cov teeb liab hluav taws xob tuaj yeem tso tawm rau lub khoos phis tawj tswj lub ntsiab rau lub sijhawm saib xyuas cov txheej txheem nruam casting.

1) Los ntawm kev siv cov khoom no, peb tuaj yeem tshawb xyuas qhov kub thiab txias ntawm tundish molten steel thiab qhov sib txawv, siv cov kev ntsuas hauv lub sijhawm los tiv thaiv cov ntshav tawm los yog dej nozzle clogging vim siab dua lossis qis dua ntawm cov hlau molten, txo qhov poob vim los ntshav. -tawm thiab khov qhov, thiab lub sijhawm tsis ua haujlwm vim muaj xwm txheej, thiab yog li txhim khu kev khiav hauj lwm ntawm lub tshuab casting.

2) Los ntawm kev siv cov khoom no, peb tuaj yeem paub qhov kev hloov pauv ntawm tundish molten steel kub.Raws li txoj cai hloov pauv no, peb tuaj yeem muab cov txheej txheem thev naus laus zis tsim nyog rau cov txheej txheem tom ntej, xws li steelmaking thiab refining.Los ntawm kev ua qhov no, peb tuaj yeem tsis tsuas yog txo qhov kub ntawm 15 txog 20 ℃, tab sis kuj ua kom cov txheej txheem nruj, nce qib tswj thiab ntsuas qhov tseeb.

3) Nrog rau qhov ntsuas kub kom raug, qhov system no tuaj yeem txo qis ntawm superheat los ntawm 5 txog 10 ℃.Los ntawm kev txo qis ntawm superheat peb tuaj yeem tau txais qhov dav equiaxed siv lead ua cheeb tsam, txo qhov chaw sib cais ntawm cov cam khwb cia, zoo kom tsis txhob muaj qhov tsis xws luag ntawm looseness, shrinkage kab noj hniav thiab tawg, thiab txhim kho steel zoo;nyob rau hauv lub caij no, los ntawm kev txo qis ntawm superheat peb tuaj yeem ua kom nrawm nrawm thiab steel zoo.Daim ntawv thov kev coj ua pov thawj qhov ntsuas qhov ntsuas kub no tuaj yeem ua kom nrawm nrawm ntawm 10% ntawm qhov nruab nrab.